Equipment and Technology Used in Asbestos Abatement

Immediate safety concerns arise when homeowners discover hazardous materials during a renovation or real estate transaction. You want assurance that the removal process protects your family and property. Professional remediation involves specialized gear designed to contain dangerous fibers. We will examine the essential equipment and technology used in asbestos abatement so you know exactly how we maintain a safe environment in your home.

Containment and Isolation Systems

Technicians must separate the work area from the rest of the house before removal begins. We construct critical barriers using heavy-duty, 6-mil polyethylene sheeting to seal off doors, windows, and vents. Once we seal the area, we install negative air pressure machines.

These powerful devices create a pressure differential that prevents air from escaping the workspace. Even if a breach occurs in the plastic containment, the air flows inward, not outward. These machines feature high efficiency particulate air (HEPA) filters, which trap 99.97 percent of particles as small as 0.3 microns. This technology scrubs the air continuously, ensuring fibers remain trapped within the machine’s filtration system rather than drifting into your living room.

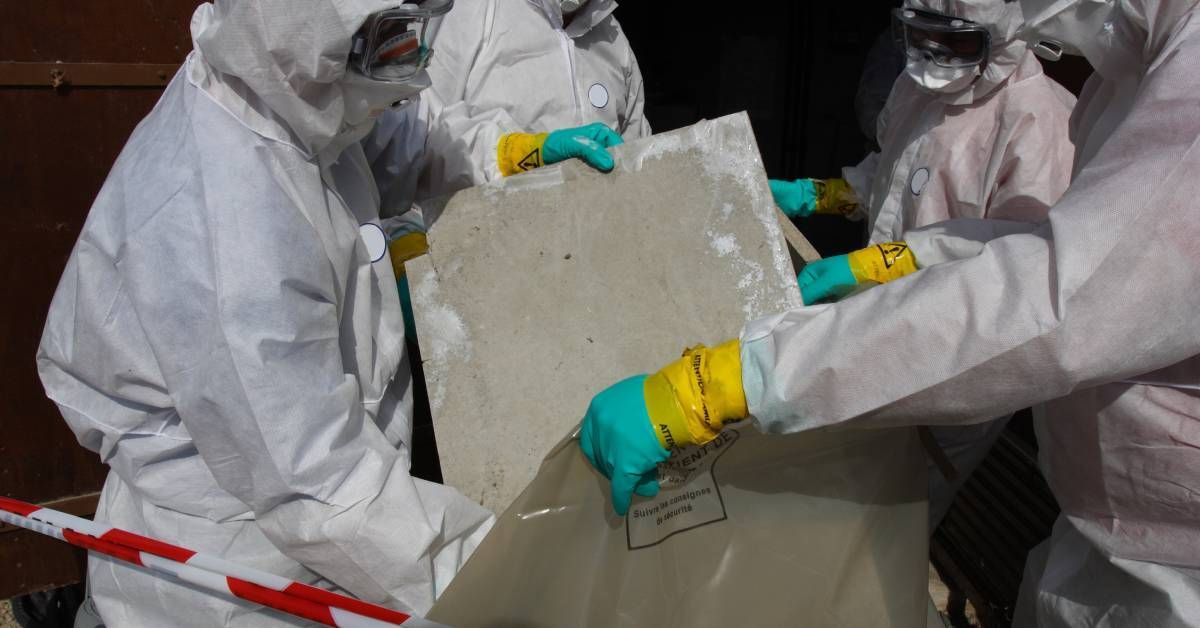

Personal Protective Equipment (PPE)

Technicians require rigorous protection to perform their work safely. Regulatory standards mandate gear to prevent inhalation of fibers and skin contact. A professional asbestos abatement company outfits every worker with disposable coveralls, often known as Tyvek suits, which they seal at the wrists and ankles.

Respiratory protection is the most vital defense. Depending on the project’s severity, workers utilize the following devices:

- Full-face air-purifying respirators

- Powered air-purifying respirators (PAPR)

- High-efficiency N-100 or P-100 filter cartridges

- Rubber boots and protective gloves

Specialized Removal Tools

Attempting to remove asbestos dry releases dangerous clouds of dust. To prevent this, professionals utilize amended water, which is water mixed with specialized surfactants. This mixture penetrates the material more effectively than plain water, locking fibers in place before disturbance occurs.

Standard household vacuums pose a severe risk as they blow microscopic particles back into the air. We rely exclusively on industrial-grade HEPA vacuums. These units capture fine dust and debris on walls, floors, and surfaces, ensuring the area passes visual inspections and air quality tests.

Air Monitoring Devices

Verification provides the final layer of safety. Independent hygienists use air sampling pumps to test the environment throughout the project and upon completion. These pumps pull air through a collection filter for a specific duration. Laboratories then analyze these filters to confirm fiber counts are below regulatory limits.

The equipment and technology used in asbestos abatement ensure the job meets strict safety standards. At Air Safe, we invest in the best technology to provide peace of mind for every client. Don’t leave hazardous material removal to chance. Contact Air Safe today for a free estimate, and let our experienced team protect your home.